|

|  | ||||||

|---|---|---|---|---|---|---|---|

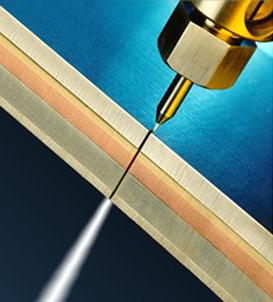

Water Jet

cutting systems use a combination of water and an abrasive grit

called "Garnet" to cut through materials considered too costly

to cut by conventional cutting methods. Using small amounts of

water, while eliminating the friction caused by tool-to-part

contact, abrasive Water Jet cutting avoids thermal damage which

can adversely affect metallurgic properties in materials being cut.

The ability to pierce through material also eliminates the cost of drilling

starter holes. Because abrasivejet cuts with a narrow kerf,

parts can be tightly nested thus maximizing material usage. | |||||||

|

Our staff is always eager to quote your project. e-mail .dwg

or .dxf files to

sales@feilhauers.com. |

|||||||